Sewage treatment plant modernisation in Seesen with support from PASCHAL

With two formwork systems - TTR Circular Trapezoidal Girder Formwork and the LOGO.3 - supplied by PASCHAL, the sewage treatment plant in Seesen, Harz, is being expanded and also optimised in order to reduce the energy requirements by around 102,000 kWh per year.Modernisation of the aeration stage in terms of energy

As part of the biological purification process, the aeration stage represents the heart of the sewage treatment plant. The waste water pre-treated in the mechanical purification stage arrives here and is fed through 3 round aeration tanks with a total capacity of more than 5 million litres. In the aeration tanks, oxygen is added to the waste water using surface aerators to imitate the principle of water self-purification in a concentrated form. As happens in nature, microorganisms break down carbon compounds, nitrogen compounds, organic impurities and any phosphates contained.

The existing aeration stage is equipped with rotary aerators dating back to 1960 and 1968. These surface aerators, measured by the amount of air introduced, have a very poor energy balance and are responsible for the power peaks when the sewage treatment is operating. As part of the development of the aeration stage, sustainable energy modernisation of the aeration technology is planned by converting to a micro-bubble compressed air system. In addition, modernisation work will be carried out on other parts of the plant, with the aim of reducing the energy used and optimising the degree of purification.

The sewage treatment plant uses approx. 1.124 million kWh a year; around half, in other words 608,000 kWh of the electricity required is already generated in its own cogeneration plant. The rotary aerators in the aeration tanks currently consume around 422,000 kWh a year. By modernising the facilities, around 102,000 kWh less energy is expected to be required in this area, which equates to a reduction of the annual CO2 impact by 58.7 tonnes of CO2 according to the plant planning.

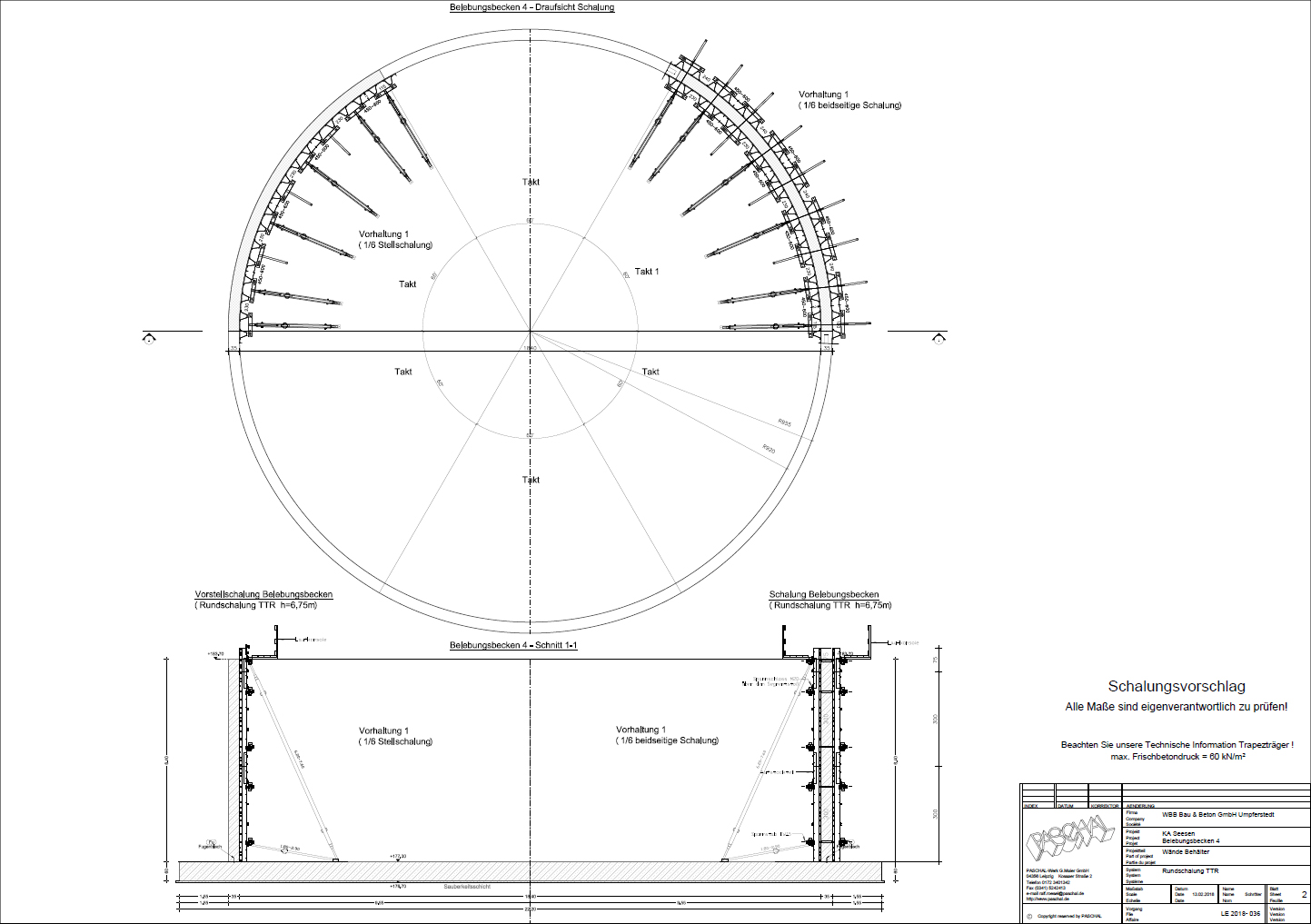

One of six concreting cycles for the new construction of aeration tank no. 4. The complete wall height of 6.75 m is concreted to a thickness of 35 cm in one cycle.

TTR based on experience

The construction company carrying out the work, WBB Bau & Beton GmbH from Umpferstedt, is well aware of the benefits of TTR - Trapezoidal Girder Formwork. That is why only TTR came into consideration for them in the first stage of this project too.

The new construction of aeration tanks no. 4 and no. 1 in conjunction with the connected collection and distribution shaft is necessary beforehand in order to tackle the renovation of tanks 3 and 2 once the new aeration tanks have been completed.

Aeration tank no. 4 is currently under construction and is being completely executed with the already radius adjusted TTR – Circular Trapezoidal Girder Formwork. For this purpose, the specified concrete tank was divided by the PASCHAL preliminary formwork planning into 6 equal concreting cycles with an internal diameter D(i) = 18.40 m and a formwork height of 6.75 m. In accordance with the construction schedule, around 220 m² of TTR - Trapezoidal Girder Formwork will therefore be kept on the building site.

100 m² of the LOGO.3 wall formwork system will be held for straight wall and shaft sections as well as the fittings.

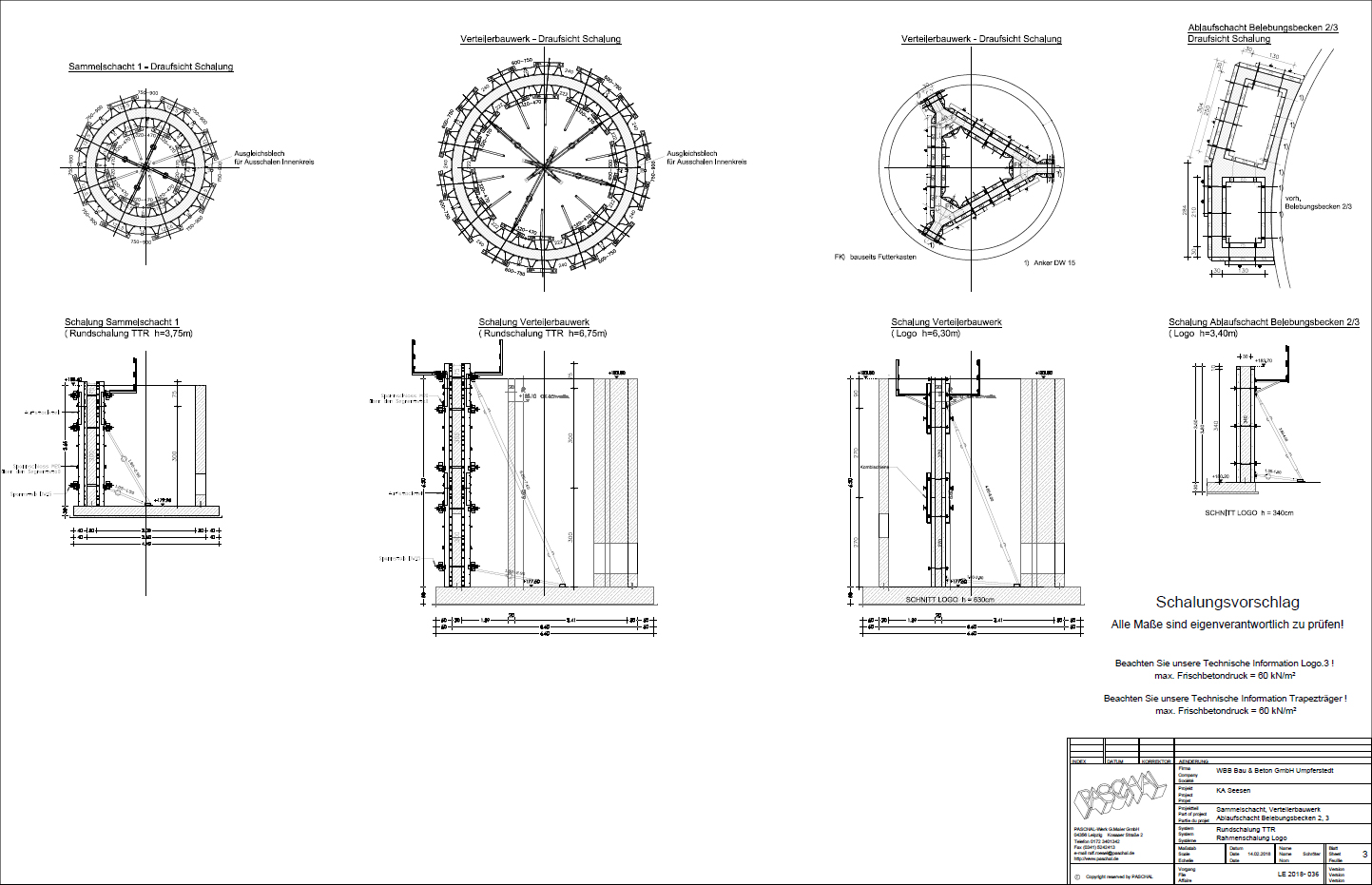

The distribution structure in the photo on the right, with an internal diameter of 5.60 m and a wall height of 6.75 m, has already been concreted.

Pictured on the left, the TTR – Circular Trapezoidal Girder Formwork is assembled as inner formwork for the collection shaft.

The smaller distribution tank with an internal diameter of 5.60 m and a formwork height of 6.75 m is divided into 2 cycles, which is why 125 m² of TTR - Trapezoidal Girder Formwork is sufficient for this.

The collection shaft with an internal diameter of 3.00 m will be formed and concreted completely in one cycle at a formwork height of 3.75 m using around 80 m² of TTR - Trapezoidal Girder Formwork.

The construction of aeration tank no. 1 with an internal diameter of 17.91 m and a surrounding height of 6.80 m is planned for the start of 2019.

The 100% system compatibility of TTR and LOGO.3 makes it easier for the building company to execute all the concrete construction work.