PASCHAL needed twice for the B34 bypass

According to the Project Information System (PRINS), the B34 bypass is part of the German Federal Transport Infrastructure Plan 2030 and, based on the calculation data from 2014, is estimated at 12.5 million euros.

Bridge structure 5 is an engineering structure that was completed for the B34 bypass with the support of PASCHAL as part of the German Federal Transport Infrastructure Plan 2020.

PASCHAL is supporting its regular customer, Schleith GmbH Baugesellschaft, with complete services and systems for engineering structures 4 and 5 on the new 2.132 km long road.

PASCHAL is offering the contractor everything for this infrastructure project from a single provider. The construction firm has a competent contact person at its side for all relevant formwork, scaffolding and shoring system work. From formwork for foundation to the static calculation of the superstructure formwork, not forgetting the complex custom formwork, everything is covered.

Construction of new transport infrastructure to relieve congestion in inner cities

The A98 High Rhine Expressway currently ends after the single-lane section 10.2 Tiengen-Lauchringen at the junction with the B314. The new B34 will continue the A98 as a link between the A98 to the west and the existing B34 to the east of Lauchringen. It runs in a west-east direction across the Oberlauchringen district of the Lauchringen municipality.

The planned route of the new B34 is located entirely outside of built-up areas and will be built as a single-lane dual carriageway, functioning purely as a connection.

Wall formwork LOGO.alu in use for the abutment of construction axis 10 under the Deutsche Bahn auxiliary bridge, combined with work and concreting platforms made up of platform brackets and Secuset, the reliable lateral protection system. Hinged bracing provide a secure stiffener for the wall formwork LOGO.alu, combined with the hinged corner post.

Wall formwork LOGO.alu in use for the abutment of construction axis 10 under the Deutsche Bahn auxiliary bridge, combined with work and concreting platforms made up of platform brackets and Secuset, the reliable lateral protection system. Hinged bracing provide a secure stiffener for the wall formwork LOGO.alu, combined with the hinged corner post.

Engineering structure 4 – the railway bridge

In order to minimise the effect on train traffic and to keep interruptions brief, the bridge was constructed from a mix of prefabricated parts and in-situ concrete structures.

Construction firm SCHLEITH GmbH used PASCHAL's wall formwork LOGO.alu to form and set up the in-situ concrete structures, abutments and wing walls.

The low dead weight of the formwork panels was particularly important here, as they could also be moved by hand – a significant advantage when building under the tracks. Using wedge clamps, the wall formwork LOGO.alu panels are quickly and securely connected to each other and, thanks to the stable frame profiles, only require 2 tie points for a panel height of 2.70 m.

On site, the formwork for all the visible concrete surfaces of the abutments and wing walls was covered vertically with boards planed on one side.

The permissible fresh concrete pressure of the wall formwork LOGO.alu of 60 kN/m² according to DIN 18218 made it possible to form and pour each of the 4 wing walls as well as the two abutments in a single cycle.

The abutment transitioning to the wing was formed two-sided with wall formwork LOGO.alu.

The abutment transitioning to the wing was formed two-sided with wall formwork LOGO.alu.

Every angle precisely formed

As is customary with all PASCHAL systems, the systems, accessories and special parts are compatible with each other. This allowed the formwork to be aligned exactly at the four specified angles for each abutment. Hinges turned the stiffening multi-walers into a hinged bracing, thereby completing the stiffening panels with a force-fitted connection around the corners.

Safe at any height

To achieve forming and concreting heights of over 6.00 m, the wall formwork LOGO.alu was equipped with safe work and concreting platforms made up of platform brackets and Secuset, the reliable lateral protection system in accordance with the DIN EN 13374 safety standard.

Upon completion of the formwork and scaffolding work for structure 4, site manager Matthias Moser and foreman Ernst Sutter summarise the process: The decision to use LOGO.alu rental formwork was perfect because construction was taking place underneath busy tracks and the panels could be transported and assembled quickly and easily by hand. The light weight and the dimensions of the panels also ensured low transport costs.

It was with a positive experience of working with PASCHAL as a partner that the two construction specialists from Schleith GmbH Baugesellschaft embarked on structure 5.

After successful completion of the reinforced concrete work on structure 4, the formwork and scaffolding work on structure 5 is fully underway.

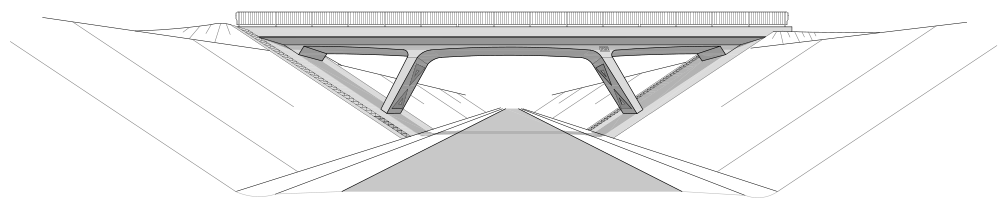

Engineering structure 5 – bridge for agriculture

For structure 5, a bridge for agriculture, the PASCHAL complete package included the formwork planning, the formwork, scaffolding and shoring components, the special timber formwork panels and PASCHAL Maturix, the concrete monitoring system from PASCHAL.

The wall formwork system LOGO.3 was used to form the two tapered bridge piles, with a 60°inclination, within the system. At the base, the piles are 40 cm thick and at the "head", they measure 60 cm.

The 2.70 m wide pile formwork rises up to 6.20 m in height and was constructed completely with the wall formwork system LOGO.3. When the inclined and tapered construction was being formed, the tie rod could be passed through without the use of on-site timbers, which helped speed up the work process enormously.

The range of panels of the wall formwork LOGO.3 used for the abutments meant a significant reduction in the special timber formwork.

The concreting brackets, which are able to compensate for the pile inclination and create a horizontal running surface, made the forming, reinforcing and concreting processes safe while also achieving a speedy and successful final result.

The concrete monitoring system, PASCHAL Maturix, assured a safe concreting process.

Construction firm SCHLEITH GmbH used the construction of one of the two bridge piles as a test for further optimisations in concrete construction. The wireless PASCHAL Maturix sensors provide a direct insight into the setting process of the concrete structure.

Using reference values, the sensors transmit the heat of hydration in real time to the web-based software, from which the strength achieved can be determined.

Additional software features such as automatic documentation and alarm settings guarantee a continuous overview of everything happening in the concrete structure.

During the test in Oberlauchringen at engineering structure 5, one sensor was sufficient to test and demonstrate the concrete maturity. The test application was convincing enough for the concrete monitoring system, PASCHAL Maturix, to also be used for the 2nd pile. An amplifier from PASCHAL was used to access the signal from a web browser in the home office of site manager Matthias Moser and foreman Ernst Sutter.

The relief was achieved by placing the mould inserts on the wall formwork system LOGO.3.

The relief was achieved by placing the mould inserts on the wall formwork system LOGO.3.

Abutment and superstructure in one formwork

Once the two bridge piles had been constructed, the abutments were formed, the supporting shoring structure was erected, the H 20 beams were placed, and the safety level as well as the prefabricated special timber formwork panels were installed.

To ensure that all the constructions would fit together on site, the special formwork panels were also coordinated by PASCHAL.

To ensure that the work above the supporting scaffolding, at a height of around 4.00 m, could be carried out quickly and safely, a safety level was also planned by PASCHAL on behalf of construction firm SCHLEITH GmbH.

The edges, which were also included in the PASCHAL complete formwork package, completed the in-situ concrete structures.