PASCHAL creates the basis for a majestic office building complex

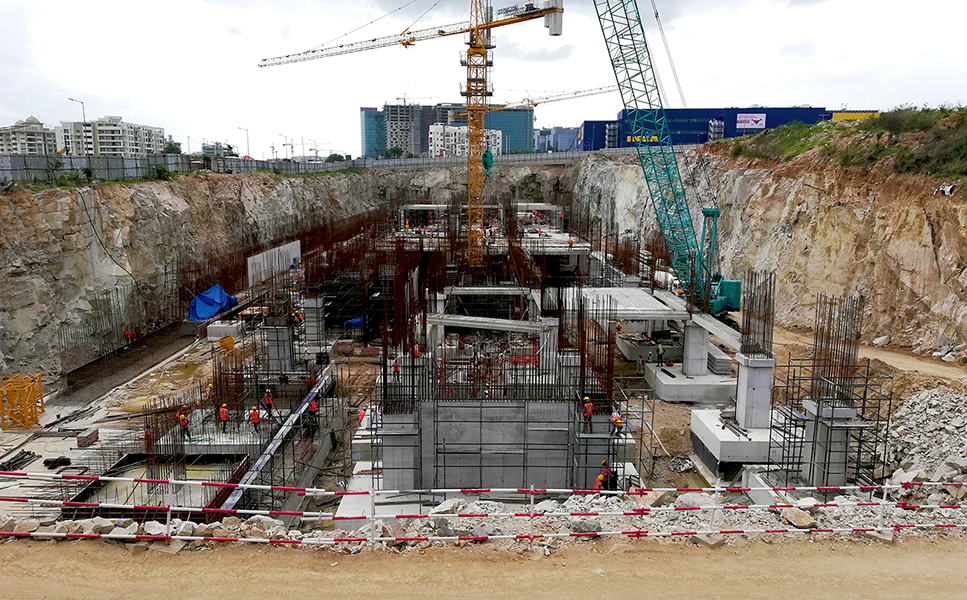

In Hyderabad (India) the 105-metre-high Aurobindo Galaxy Towers are currently being built. PASCHAL Form Work (India) Pvt. Ltd. is supplying the formwork for all the cast-in-situ parts for this project and thus enabling the construction work to proceed quickly and easily.The Aurobindo Galaxy Towers are a 105-metre-high office building complex at the heart of "Hitech City", in the Hyderabad Knowledge Park. Once completed, the Galaxy Towers are expected to be the highest business office towers in Hyderabad – built as a reinforced concrete construction.

The building consists of 4 basement levels and 24 upper floors, providing a floor space of around 176,000 square metres. Also included in the plans are cafés and restaurants, shopping facilities and a catering area with 800 seats.

Besides a health centre and a company nursery, an underground car park with parking on four levels is also planned.

Formwork from PASCHAL for efficient building progress

The concrete parts in the underground levels are being cast in situ. Due to its versatility and the extensive range of panels, Aurobindo realty & Infrastructure Pvt. opted for the Modular universal formwork from PASCHAL.

For the foundations, pillars, core walls and retaining walls with a concrete area of around 80,119 square metres, PASCHAL Form Work (India) Pvt. Ltd. supplied 2,240 square metres of formwork material in total.

In compliance with German standards, around 50 per cent of the formwork material was delivered within 15 days so as to support the project teams according to their project requirements.

The Aurobindo Galaxy Towers will be the highest office building complex in Hyderbad after their completion. For a contemporary, modern look, the building will feature an elegant glass facade combined with a modern design.

The Aurobindo Galaxy Towers will be the highest office building complex in Hyderbad after their completion. For a contemporary, modern look, the building will feature an elegant glass facade combined with a modern design.

Solid foundations thanks to the Modular universal formwork

For this project, it was necessary to make approximately 20 different sizes of foundations. The sizes varied from 3 x 3 metres to 8 x 6 metres. With the versatile Modular formwork, PASCHAL was able to provide the optimal formwork solution for the foundation area.

The simple formwork connection technology also ensures that work progresses easier and faster compared to conventional formwork.

By using the Modular universal formwork, it was possible to produce the large individual foundations in the appropriate quality very quickly.

During the second construction stage, pillars measuring 1 x 1 metre and 1.4 x 1.4 metres, each with a height of 3.75 metres, as well as retaining walls, shear walls and core walls of various shapes were built.

The extensive range of PASCHAL Modular formwork panels allows the elements to be combined in many ways. All the geometric structures of the shear and core walls were therefore produced with efficient arrangement of the Modular formwork.

All in all, around 144 square metres of Modular formwork were used to concrete the pillars.

All in all, around 144 square metres of Modular formwork were used to concrete the pillars.

Perfect formwork and formwork planning to overcome any challenge

In addition, the exact planning on the part of PASCHAL guaranteed that the available material could be used for all the other walls without disrupting the schedule.

Another challenge that needed to be overcome during the course of this project was the precise scheduling for the concreting and connecting of the vertical structures and the pre-fabricated slabs. By using the Modular universal formwork, it was possible to keep exactly to the timeframe with outstanding concrete results.

Modular formwork from PASCHAL - the tried and tested universal formwork

Modular universal formwork demonstrates its versatility, adaptability and flexibility - whether for foundations, walls, shafts, curvatures, columns or beams - time and time again. Another benefit of the PASCHAL Modular formwork lies in its durability and robustness. Consequently, the formwork material can easily be reused even after many applications.

The use of Modular universal formwork on this project enabled time and costs to be saved for a wide range of areas:

- Shorter assembly and dismantling of the formwork

- Prevention of complements by a carpenter

- Simple handling of the system

Thanks to the extensive range of panels, the shear and core walls were also built using the PASCHAL Modular universal formwork.

Thanks to the extensive range of panels, the shear and core walls were also built using the PASCHAL Modular universal formwork.