PPL 11.0 – the BIM-capable software for efficient and transparent processes in formwork planning

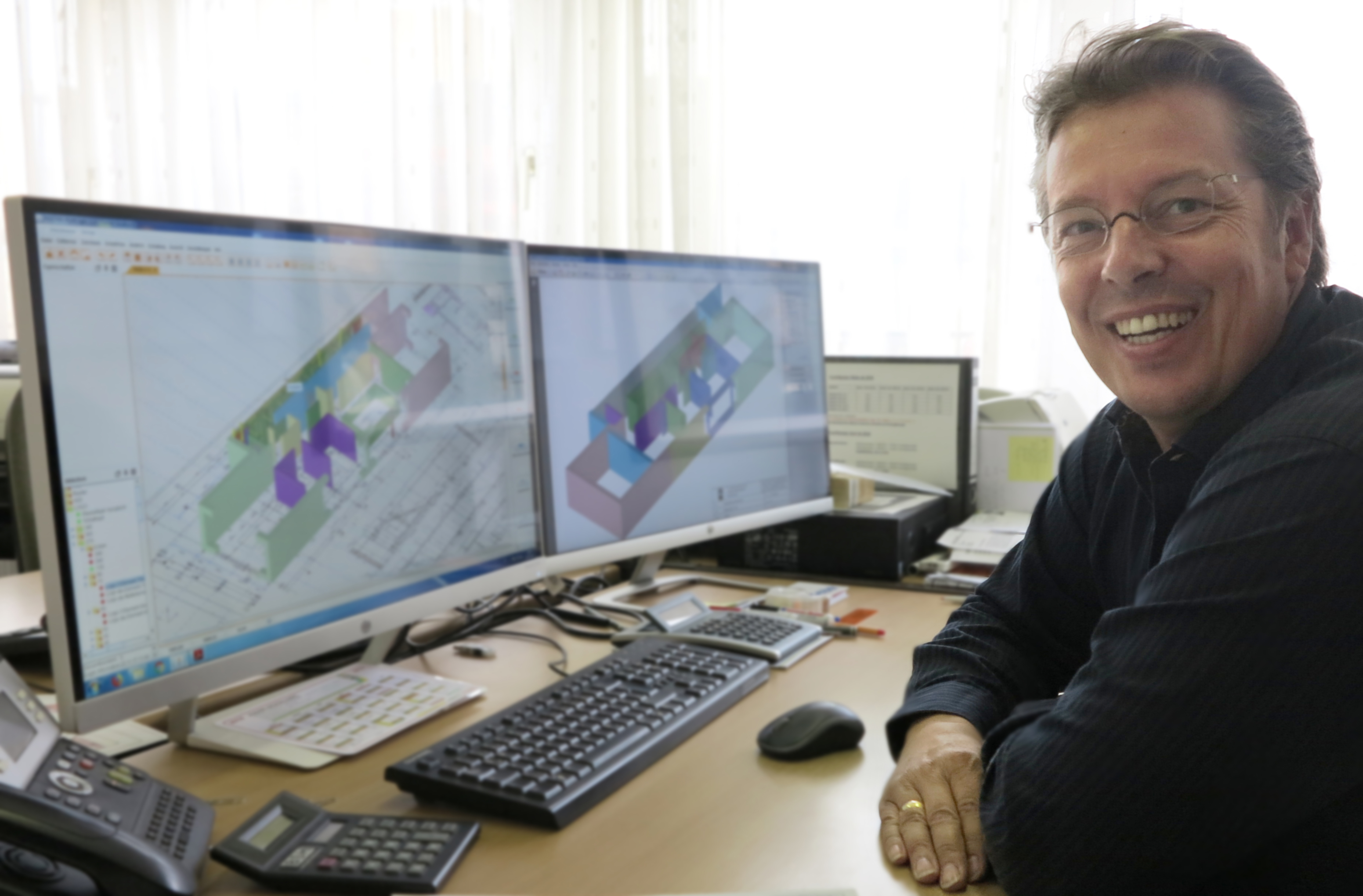

Modern formwork planning software such as PPL 11.0 supports communication between everyone involved in the project by presenting the planning results in 3D. At the same time, the software ensures that planning requirements are quickly and reliably implemented, even for complex projects."The requirements and the scale of projects in formwork planning have increased considerably. In order to meet these demands, efficient and precise work preparation is absolutely essential nowadays," says Lothar Riebesell, an employee in the special field of formwork systems at Hahn Schalung.

Builders' merchant Hahn Schalung from Frechen was founded in 1899 and is steeped in tradition. Hahn depends upon top-quality products and a high degree of economic efficiency for its success. This also holds true for the Hahn company itself, which has for many years offered a professional rental service for concrete formwork, including formwork systems and planning services. Hahn has been a long-standing trading partner of formwork manufacturer PASCHAL and offers the PASCHAL wall formwork systems in its rental park.

Quick & reliable: Automated work preparation with PPL

For formwork projects, builders' merchant Hahn sets great value on effective communication with customers, as well as planning certainty with the lowest possible planning expenses. As such, the use of appropriate software is of particular importance to the company.

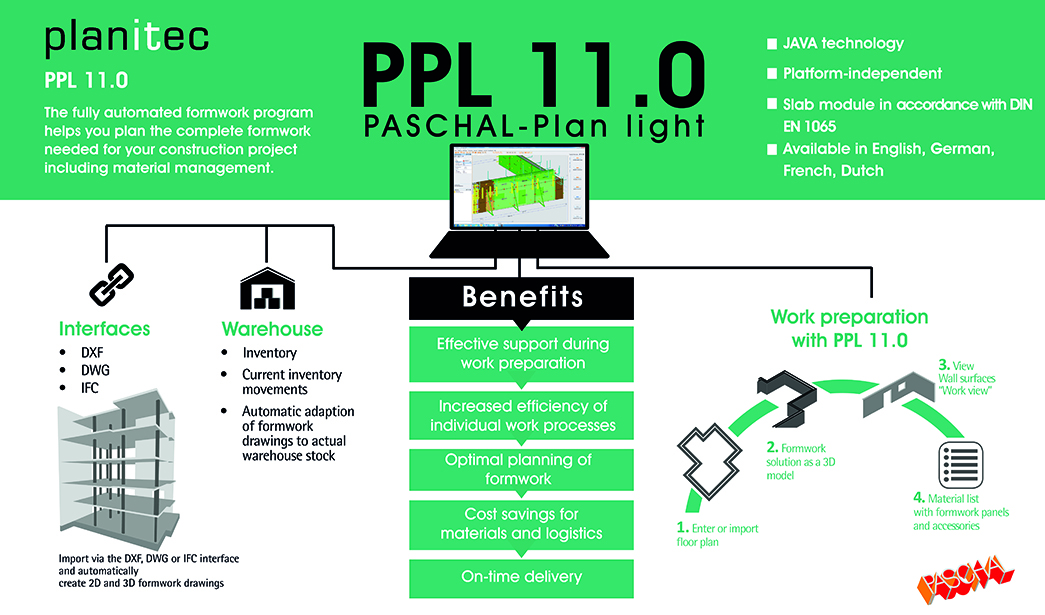

Since 2012, Hahn Schalung has been working with PASCHAL Plan Light from planitec, the IT subsidiary of PASCHAL, and is currently using the new BIM-capable version PPL 11.0. PPL 11.0 allows formwork plans already available in DXF, DWG and IFC format to be imported directly into the formwork planning software. If the DXF or DWG export files are of a high quality, the software can detect the walls on each layer, which are then automatically generated in 3D. Furthermore, the integrated IFC interface enables entire building models to be imported and immediately edited. A clear benefit here is the option of dividing the walls as well as the slabs into phases and using the system-independent H20 or filigree slab modules.

“In addition to successfully communicating with the customer, the support provided by automated formwork planning, interface technology and the 3D presentation of formwork plans is essential for us." - Employee in the special field of formwork systems, Hahn Schalung.

Successful project implementation: What is important for modern formwork planning?

"Today, we import up to 95% of our plans into PPL using the DXF interface. Automatically importing formwork plans has therefore become a prerequisite for us to be able to work effectively," says Lothar Riebesell.

In addition to these partially automated processes and the sophisticated interface technology, communication with the customer during project planning is still priority number one for Mr Riebesell. The 3D presentation of the planning results from PPL helps him greatly to interact successfully with the customer. "3D images allow us to see the important details more clearly. This makes communication easier with everyone involved in the project. It allows important details, such as the phases, to be clarified in advance. This reduces the risk of time-consuming changes to the plans later on. Not only do we save time, but we also increase customer satisfaction," explains Lothar Riebesell.

Hahn uses the 3D presentation of the formwork construction effectively even with more complex projects: "For example, during the preliminary planning of the wheelchair-accessible community centre Forum am Deutzer Dom, we were able to use the drawing tools to show the customer the layout of the future fair faced concrete walls over the various floors," says Mr Riebesell.

Comprehensive range of functions: From material lists for each phase and material management to customised adjustments

PPL 11.0 can be used to create standard material lists for each phase with the required number of formwork panels and the necessary accessories. In addition to this function, planitec has programmed a customised report for builders' merchant Hahn to prepare offers automatically. "We can use PPL 11.0 to create high-quality offers with material lists for each phase of the project, even for more complex projects, in a very short space of time. This not only considerably reduces our workload but also additional error sources," explains Lothar Riebesell.

Range of functions and work preparation with PPL 11.0 from PASCHAL.

"Warehouse" - material management with PPL 11.0

The "Warehouse" module in PPL 11.0 allows the user to query dynamically the material availability in the warehouse. This means that not only the current inventory is recorded, but all the inventory movements as well. For instance, if material is returned to the warehouse during the project, the formwork plans can be automatically adapted to the available formwork material. Warehouse therefore allows us to use the formwork inventory in an optimal way. The shortages list can also be used to quickly react to any bottlenecks and any missing material can be rented additionally, for example.

Lothar Riebesell is convinced that the BIM-capable PPL 11.0 is a sustainable tool for formwork planning and he is looking forward to seeing what technical developments the future holds, particularly with regard to BIM and the IFC interface integrated in PPL 11.0.