Conservation of species and preservation of historic buildings combined with regenerative energy generation

The conservation of species and preservation of historic buildings is being combined with regenerative energy generation at the weir system in Kirschbaumwasen in Germany. The construction work is being carried out by Schleith GmbH construction company with intensive support from PASCHAL.An extraordinary construction site with numerous special features

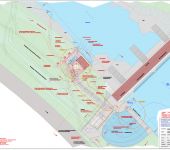

The Kirchbaumwasen construction site presents many challenges that were particularly evident during construction work. Many new structures have to be connected to the existing buildings and only limited space is available since the construction site is enclosed between a main road and a railway line and due to the high level of the terrain and the hydrological conditions as the water level fluctuates greatly during the course of the day.

One construction site - 3 construction phases

The construction work to be carried out by Schleith GmbH and PASCHAL as part of the renovation and modernisation of the Kirschbaumwasen weir system can be divided into three phases.

Phase 1 incorporates the renovation in sub-sections of the fish entrance and exit areas in the upstream section.

Phase 2 is the new construction of the extremely complex discharge building.

The 3rd phase includes the intake channel which connects the basin of the fish entrance and exit areas in the head water with the upper connection of the fish lift in the discharge building.

On the right of the photo is the discharge building with parts of formwork from LOGO.3. The photo also demonstrates the special topographical and hydrological features on the construction site.

On the right of the photo is the discharge building with parts of formwork from LOGO.3. The photo also demonstrates the special topographical and hydrological features on the construction site.

Phase 1 in the head water

During construction phase 1, renovation in the area behind and underneath the baffle and the strengthening of the crosspiece along its entire length was to be carried out for the full restoration of the ecological passageway. The extraction inlet had to be drained for one week for this purpose. This "dry period" was not allowed to last longer than this, as per the specifications of the client, an energy provider.

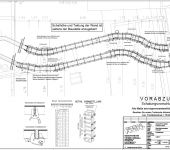

The formwork and scaffolding work for two columns with a height of 9.45 metres had to take place between the riverbed and the lower side of the crosspiece, and had to be connected in a force-fitting manner. One column was realised single-sided against the existing building in two concreting steps of 1 x 4.50 m and 1 x 4.80 m and the formwork was produced entirely in the system, i.e. using panel elements from the PASCHAL product range, despite its trapezoidal cross-section. The rounding off in the direction of the Murg River was created using a curved formwork insert.

The double-sided formed column was realised with the LOGO.3 formwork system using the same height cycles. The formwork structure was also equipped with work platforms for safe working from the PASCHAL product range. Formwork for the semi-circular abutment head was also created using a wood insert supplied by PASCHAL. At the end of the abutment which ends with a conical-shaped cross-section, a 9.45 metre long U-shaped steel piece was combined and set in concrete vertically with the LOGO.3 formwork.

The new construction of the discharge building, phase 2

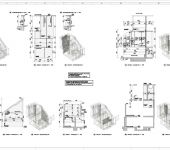

The 3D model demonstrates the complexity of the complete structure. All of the building equipment, the fish lift technology and the fish lift itself have to be taken into consideration during the formwork planning. Firstly, because technical components are installed in the building shell construction phase where formwork and concreting are subsequently carried out, and secondly because of the collision analysis. Of course, no bracing, support, anchoring or shoring etc. may be allowed to collide with the building or fish lift technology.

The PASCHAL planning team took all of this, as well as the confined conditions on the construction site and the economic challenges into consideration. Site manager Florian Bühler was extremely enthusiastic when he talked about the smooth coordination and work preparation with the PASCHAL project team, which also included the corresponding technical formwork specialist.

"With PASCHAL, everything is flexible, absolutely reliable and compatible with everything else. A small cog just fits perfectly and no sand (concrete) gets into the gears despite any hectic circumstances and unpredictable conditions," said Florian Bühler from Schleith GmbH.

Further reinforced concrete structures of the discharge building and the technical installations, such as the cylinder of the fish lift (the yellowish tube), were prepared for the concreting work with formwork and shoring systems from PASCHAL. The sandbags protect the structure against the changing water levels of the Murg River.

Further reinforced concrete structures of the discharge building and the technical installations, such as the cylinder of the fish lift (the yellowish tube), were prepared for the concreting work with formwork and shoring systems from PASCHAL. The sandbags protect the structure against the changing water levels of the Murg River.

LOGO.3, combined in parts with the TTR – Circular trapezoidal girder formwork was used for constructing the concrete walls of the discharge building. Despite the challenging geometry with several wall breaks, extreme variations in the heights of the walls from 2.40 metres to 8.10 metres and differing floor levels, no filler pieces were required thanks to the wide range of panels. All formwork is produced homogenously in the system, so that there are no weaknesses with regards to the fresh concrete pressure to be taken into consideration during the concreting work.

As concreting takes place partially against the existing building, the wall formwork systems are used single-face and double-face and secured with 4- or 6-metre-high supporting jacks. PASCHAL Deck slab formwork is planned to be used for the formwork for the in-situ concrete floors.