Round-shape medical centre designed to provide all-round medical care realised using three PASCHAL systems.

A modern health centre is being constructed in Beinheim in Northern Alsace, to provide medical services to the rural community.Medical care in rural regions is also a critical issue in France. To help remedy this, a modern health centre is now being constructed in the centrally located commune of Beinheim in Northern Alsace.

Conveniently situated in the direct vicinity of the access roundabout to the east of Beinheim, no time has been lost since the ground-breaking ceremony on 30 October 2017. The reinforced concrete shell continues to grow in height and width with the systems Modular/GE formwork, TTR circular Trapezoidal girder formwork and TTK circular Trapezoidal girder formwork with clamp connection.

The TTK circular Trapezoidal girder formwork with clamp connections allows wall heights of up to 7.50 m to be formed and concreted rapidly in one cycle for the construction of the rural medical centre.

Segment-like design for a clear structure

The round building shape serves to bring unity and structure to a variety of functions. On the one hand, the workflow needs to be as efficient and harmonious as possible in the interests of patient wellbeing and, on the other hand, the building should meet aesthetic requirements: The new building must blend into the landscape and neighbouring buildings, whilst making a positive overall impression.

Both doctors and medical experts were involved in planning the design so the planners could take their needs into account.

The result is a single-storey complex spread over an area of 550 m² with six circular outside walls.

The segment-like floor plan reflects the space allocation for the various medical services. Around 100 m² have been given over to the human medicine section, a further 250 m² to physiotherapy, 40 m² to nursing and 150 m² to veterinary services.

PASCHAL systems guarantee a smoothly running formwork sequence

For soft curves, the circular Trapezoidal girder formwork from PASCHAL is the obvious choice.

That's why the local construction company KNOLL Sarl contacted PASCHAL to implement the formwork planning in line with the civil engineering drawings.

The outside wall construction of the round-shape medical centre - formed using TTK - matches the course of the curve exactly.

The outside wall construction of the round-shape medical centre - formed using TTK - matches the course of the curve exactly.

Formwork planning with the company's own PPPro software

Despite the ambitious architectural plans, only 3 PASCHAL formwork systems were required: the Modular/GE universal formwork, the TTR circular Trapezoidal girder formwork and the TTK circular Trapezoidal girder formwork with clamp connection for exceptionally rapid formwork construction and concreting of circular structures.

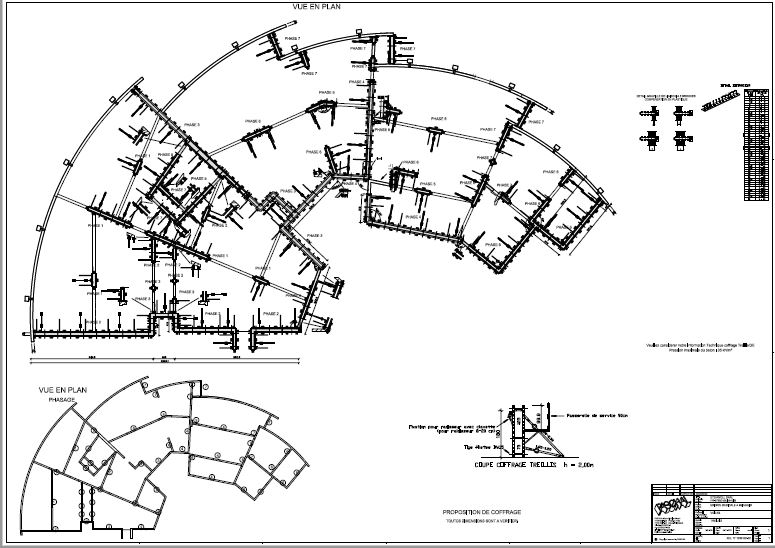

To create the 1.80-m-high straight crawl space structure, the PASCHAL application engineering department planned around 136 m² of Modular/GE formwork. This allowed 310 m² of reinforced concrete walls with a uniform thickness of 20 cm to be concreted onto the existing strip foundations in seven pouring cycles.

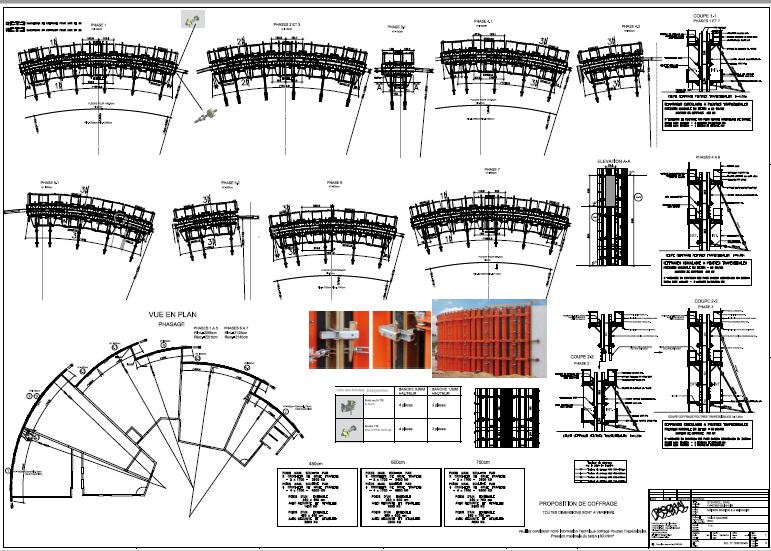

In order to integrate the arc-shaped outer wall sections into the crawl space structure, the TTR circular Trapezoidal girder formwork was used with 2 different radii. Using 54 m² of TTR circular Trapezoidal girder formwork, some 120 m² of circular reinforced concrete walls were concreted up to a height of 1.80 m over six cycles.

The circular outside walls on the ground floor were constructed at two different heights using the TTK circular Trapezoidal girder formwork with clamp connection. Concreting cycles 1 and 7 were formed and concreted at a height of 4.50 m in one cycle. In cycles 4, 5, 6 the formwork reached a height of 6.0 m. In cycles 2 and 3, a height extension raised the height of the TTK circular Trapezoidal girder formwork by 3.0 m to 7.50 m before the concrete was poured in.

The TTK circular Trapezoidal girder formwork was configured at the factory with an inside radius of 23.55 m and then delivered to the site for concreting cycles 1, 2, 3, 4, 5. For cycles 6 and 7, the construction company simply adjusted the formwork on site to an inside radius of 21.25 m.

What makes PASCHAL circular formwork so special?

The circular formwork systems allow imaginative reinforced concrete wall structures to be realised quickly, just as the circular segments of the floor plan layout were for the medical centre here in Beinheim, for example.

As the pioneer of adjustable circular formwork, PASCHAL has developed, and comprehensively tested, the Trapezoidal girder formwork based on firm basic principles to ensure it can withstand the tough conditions on site. In addition to the superior support design based on trapezoidal girders made of steel, the variable adjustment ranges are mainly supported by plywood layers specifically developed for curvatures. As such, construction companies can set up the formwork for diameters of up to 5.00 m with just one system. The 2.00 to 5.00 m version allows very small curves to be formed to perfection.

The formwork planning for the Modular/GE formwork to concrete the 1.80-m straight wall structure in the crawl space.

TTK circular Trapezoidal girder formwork with the connecting piece TTK multi-clamp for even greater formwork efficiency

To connect formwork segments quickly and easily, PASCHAL has developed the TTK for rapid clamp connection. The segments can be combined quickly, easily and seamlessly with just a few clamp connecting pieces. To ensure that nothing is lost when moving the formwork or during transport to and from the site, the clamps are stored on the formwork segments.

Formwork planning for the TTK circular Trapezoidal girder formwork for concreting cycles 1 to 7 on the ground floor.