The LTC is being developed on a construction site of more than 11,000 m² in Karlsruhe at a cost of more than 22 million euros

The harmoniously designed campus is being constructed with the constant collaboration of PASCHAL. LOGO.3, Modular formwork, Grip, TTR, PASCHAL-Deck and the new lateral protection system are being deployed for this purpose.The distinctive style elements here are circular and curved

The extraordinary design by architekten essari + lequime gmbh combines five "houses", which are characterised by many curves and organic shapes. Based on this style, the architects created an ensemble for an appealing campus featuring modern workplaces.

The organically shaped constructions and spaces, internally, as well as externally, form the basis for a positive work atmosphere for approx. 250 people initially, and are the ideal premise for expansion for the individual companies.

The construction work was initiated in mid-2018

The official construction phase of the special corporate campus began on 24 July 2018 with the earthworks, followed by the structural works. Both are performed under the responsibility of the construction company, Peter Gross Hoch- und Tiefbau GmbH & Co. KG. Thus, approximately 15.000 m² of gross floor area with a gross volume of almost 52,000 m³ are being created practically 100% as a pure reinforced concrete construction. Non-load bearing parts of the buildings are being flexibly designed to meet the respective needs of the tenants on the campus.

All the concrete structures are being shaped with the support of PASCHAL formwork and shoring systems. The new PASCHAL lateral protection system provides fall-protection on the slab edges.

The construction company relies on formwork and shoring systems by PASCHAL to implement the specified architecture, both externally, as well as internally, with the exact dimensions and shapes.

Additionally to the rounded and angular shapes of the rooms and buildings, the construction company must also master the challenge of simultaneously performing construction works on the five "houses" in parallel.

All five individual houses are situated on the shared basement level, which serves as a parking level and accommodates the media supply and disposal.

Shared facilities, such as the reception area, canteen, children's nursery, café and large areas for conferences, meetings and sport are centrally planned in buildings A and D.

From the base floor upwards, the rising structures are essentially planned as 3-storey constructions with intermittent floors above, which results in a more flexible construction design.

The open area on the first floor is loosened up by circular and curved openings.

3 PASCHAL systems in use PASCHAL: Deck for the slab above the basement floor, combined with the new fall-protection system and one Grip column formwork and behind the LOGO.3 for the construction of a short wall section.

Electronically transferred from the plan to the construction site

By way of an optical measuring instrument, the design and formwork planning data is transferred to the construction site and checked after the formwork assembly.

The smaller the radius, the more fixed points are adopted and marked for the circular formwork.

The same applies to the angled constructions of the walls. The optimum grading of the PASCHAL formwork systems enables the precise forming and concreting of the desired geometries without any on-site timber fillers.

The site managers and foreman, for whom this is their first cooperation with PASCHAL, are always surprised with the versatility of the PASCHAL formwork systems and the level of precision with which the design and planning specifications of the structural engineers can be implemented in the system.

Both site managers ─ Dimitro Huppert and Junior Talla Todem ─ are absolutely delighted with the working partnership with PASCHAL.

"The PASCHAL employees support the construction site with its particular logistic features in an exemplary manner. The PASCHAL material and formwork plans are always available when needed. This allows the numerous parallel construction operations - forming, concreting, dismantling - to be perfectly coordinated at five different construction stages simultaneously. Thus, we can perform with manageable quantities of formwork and shoring material, which ensures transparency on the construction site and translates into low construction costs for the client," according to the two young civil engineers from the construction company Peter Gross Hoch- und Tiefbau GmbH & Co. KG.

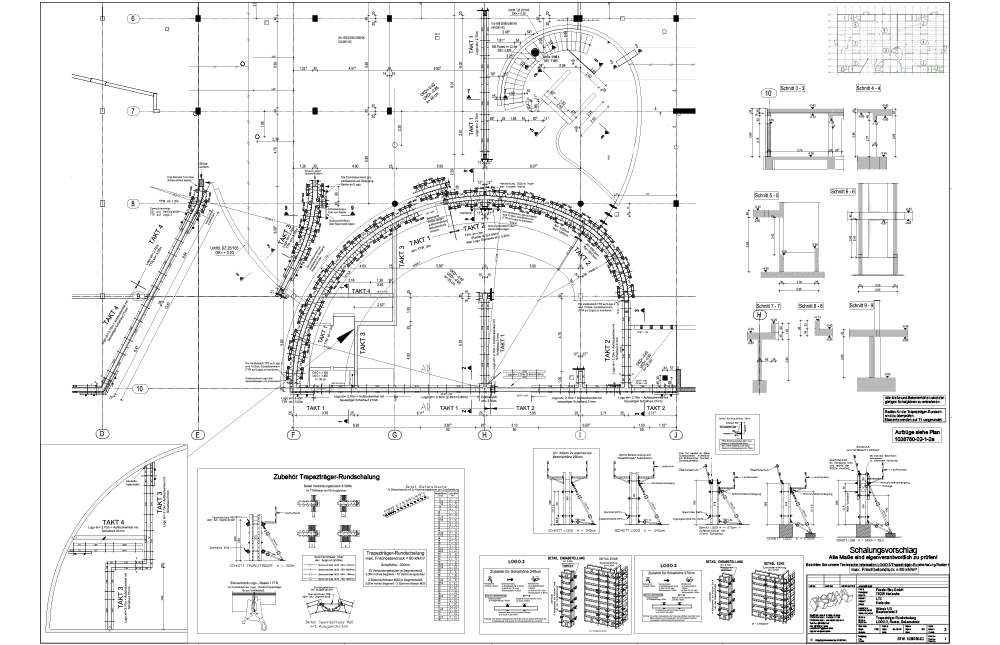

One of the many formwork plans provides an idea which special features can be implemented almost limitlessly with PASCHAL formwork systems – to the delight of architects, structural engineers, construction companies and, of course, clients, who love something special.

As 98 % of the shell is a reinforced concrete structure, the cooperation with PASCHAL is of particular importance.

The concrete slabs incl. the underground car park ramp amount to 14,900 m². The reinforced concrete slab with a thickness of 45 cm covering the basement is used as an energy storage system by means of concrete core activation and the other reinforced concrete slabs are all designed for room air-conditioning purposes (heating and cooling), by way of pipe systems encased in concrete. The reinforced concrete inter-storey slabs in houses A to F are built with PASCHAL Deck. The roof coverings of the upper floors also consist of reinforced concrete as a non-ventilated roof and will feature a green design following waterproofing.

The reinforced concrete wall areas are specified with 19,000 m². Additionally, there are the reinforced concrete columns and numerous concrete parapet constructions.

The simple and fast implementation of the lift shafts is performed with 2 sets of LOGO.3 formwork, as shaft formwork with internal dismantling posts.

The entire vertical reinforced concrete constructions are performed with approx. 700 m² of LOGO.3, around 100 m² of TTR, and 3 sets of Grip column formwork. 150 m² of Modular formwork were sufficient for the construction of the strip footings and individual foundations Approx. 6,400 m² of PASCHAL Deck (H 20 beams and slab props) are being applied for the reinforced concrete slabs.

In the case of this construction site, the unrestricted compatibility of the PASCHAL systems with each other and the respective narrow graduated sorting enable an almost 100% implementation of the systemic formwork. The basis for this is the exact formwork planning by the PASCHAL formwork experts, thus avoiding the production and installation of any additional elements by site.

The design is dominated by curves

The planned curves amount to more than 55 different radii. The TTR is used both for forming the circular walls, as well as the circular slab edges. For the very small radii and inlays for round slab openings and wall sections, the PASCHAL formwork experts designed special formwork, which matches the TTR, as well as LOGO.3 and ensures neat transitions.

Despite the absence of a requirement for exposed concrete for walls and pillars, the already dispensed concrete structures impress with their symmetrically arranged frame pattern, based on LOGO.3.

Wherever you look on this large-scale construction site, PASCHAL systems are in use everywhere.

Wherever you look on this large-scale construction site, PASCHAL systems are in use everywhere.

Everything is working out all-round on the construction site

The construction company Peter Gross Hoch- und Tiefbau GmbH & Co. KG, which is responsible for the earthworks and shell construction, describes the entire cooperation with PASCHAL as very cooperative and profitable for all involved parties - the client, the construction site teams and the construction company.

For the construction site teams, as well as for the construction company Peter Gross Hoch- und Tiefbau GmbH & Co. KG, this is their very first partnership project with PASCHAL, and they all get along very well with the PASCHAL systems right from the start due to their easy operation.

New PASCHAL fall-protection system

Another particular feature - the new PASCHAL lateral protection system is being deployed on the slab edges for fall protection.

The new lateral protection system also includes comprehensive system parts which can be individually adapted to a wide range of geometries, construction shapes and safety regulations.